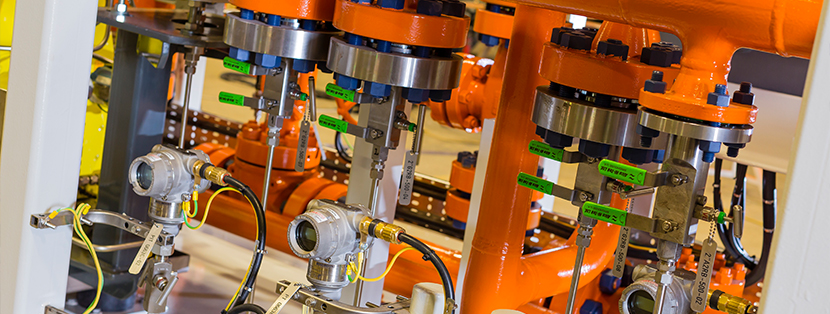

Harris Pye specialises in the fabrication of skid assemblies / process modules for a wide range of applications, which include:

- Power Generation

- Gas Generation

- Petrochemical Industries

- Onshore Oil & Gas Industries

Our services encompass the total requirements for these modules including supply of material, through fabrication, inspection, testing and assembly, including surface nish, electrical and instrumentation work, thermal insulation, packing and shipping.

- Carbon Steels incl A333 Gr 6 Low Temperature

- Stainless Steel 304L & 316L

- High Temperature Stainless Steel - 310H & 347H

- Duplex & Super Duplex Steels

- Inconel & Monel

- Cryogenic

All welding is carried out to the latest standard.

From our workshops, we are able to fabricate and assemble indoors, skids up 12 x 4 x 4 M, with piping from 1/2 “ to 24” NB & above.

Skid Modules are fabricated in accordance with the current “Pressure Equipment Directive” (2014/68/EU) and we are also able to carter for other specialised codings such as ASME and Gost (Russia).

Harris Pye uses 3D CAD for the module layout design. The designer works on a single model and 3D CAD reduces design cycle time, reduces possibility of drawing error, and ensures the proper layout for the process and proper layout for ease of operation and maintenance.

Our experienced personnel ensure that projects are completed on-time, within budget and always within the pre-agreed scope.

We deliver the following engineering systems for both adhoc and full turnkey projects:

Modular Process Plants - Skid Mounted

Our design office uses Inventor Professional, Caesar II and CADWorx Plant Design Suite to design skids and process plants for on¬shore and onshore process systems. The 3D software creates a ‘walkthrough’ so that clients are able to assess the system prior to workshop or site fabrication. This negates the risk of fabrication errors and the ensuing high costs.

Combined with P&ID’s process drawings, fabrication isometrics and detailed 2D structural drawings which transverse all engineering processes can be produced.

- Creation of P&ID process designs

- 2D/3D Modelling of Piping Stress Analysis to determine supports using AutoDesk Inventor, Autocad and CADWorx software

- Piping Stress Analysis is performed in CAESAR ll

- Piping Flow Analysis is performed in AFT Fathom

- Structural Stress analysis to determine skid scantlings using STAAD Pro or SESAM GeniE

- Generation of 3D isometric drawings for fabrication

- Ability to class detect new modelled part against existing plant model

- Easy design of frame structures

- Ability to optimise design to reduce weight of components

- Accurately determine mass and centre of gravity components

- Creation of Plant and Process System Designs